My next car gets 100 miles per gallon.

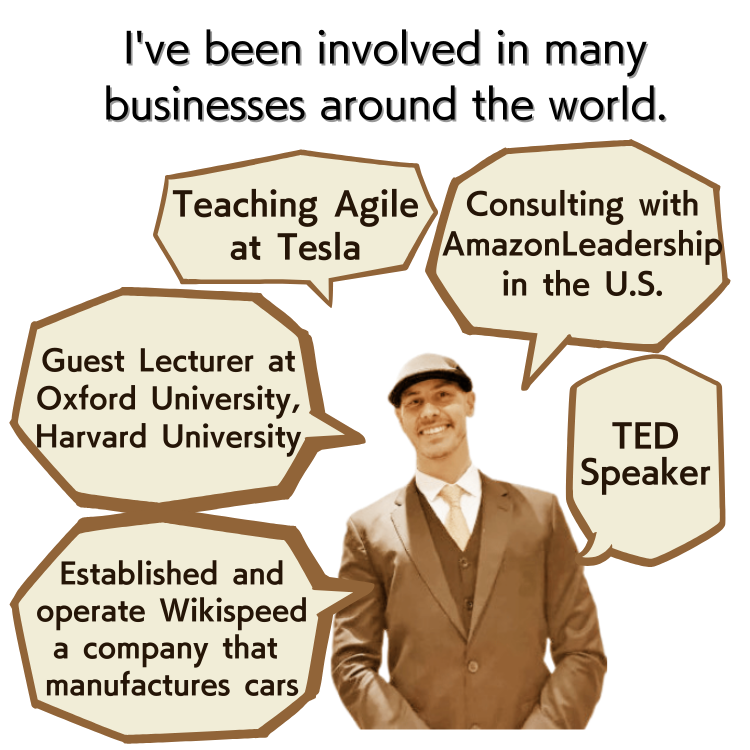

I'm Joe justice.

I'm a Seattle area software consultant and I'm a member of team wikispeed.

Team wikispeed has built a fast affordable ultra efficient safe fun commuter car and the first prototype, functional prototype was built in three months.

How is that possible?

Whenexisting cars seem to change so slowly here we see over a six-year period a mainstream hybrid car achieved an additional two miles per gallon.

Existing manufacturing processes are slow because they're very expensive to change.

If an engineer wanted to redesign this door tomorrow, they would need to wait 10 years to first pay off the current dollar mold before making another one or else lose millions of dollars.

Man this is not uncommon in manufacturing teams for them to run on 10 to 25 year development cycles.

Old software teams used to run the same way.

We use seven-day development cycles.

This is how new software teams run and it allows us to make changes very quickly.

In 2008 the progressive insurance automotive Xprize announced a 10 million dollar prize purse and an international challenge to see if it were even possible to build 100 mile per gallon cars to road-legal safety specifications.

The closest thing we had in 2008 were like bobsleds.

They achieved more than 100 miles per gallon but they held one occupant and they didn't meet road-legal safety requirements.

I joined the XPrize too but in the beginning it was just me.

But I decided to blog about everything that went well and everything that didn't go well and everything I was learning and through social networking tools a team came to assist.

And in three months later, we had the car that we campaigned in the XPrize and a volunteer team of 44 team members in four countries.

We tied for 10th in the mainstream class that meant we outlasted more than 100 other cars from companies and universities around the world.

We do this by modeling our team to develop the car after modern software teams.

We use techniques with funny sounding names like agile, lean and scrum.

These methods all helped us make changes quickly.

Right after the XPrize we were invited to the largest auto show in the world January 2011 in Detroit Michigan.

We knew we wanted a more beautiful car, a more aesthetic car but we also knew that for one car body it would cost us at least $36,000 and three months lead time.

So I took time off my day job and I went to composite school.

I came back to the team and we made small models of the car and iterated a composites process that ended up letting us build our car body in structural carbon fiber in three days for eight hundred dollars.

You guys are awesome, thanks so much.They put us on the main floor of the Auto Show between Ford and Chevrolet.

Lucky for us the car was beautiful.

That car went on to be featured on the Discovery Channel, popular science Popular Mechanics, the New York Times online, the National Geographic Channel, Wired magazine, the Forbes billionaire club linked to us and others.

Now and this has been a six-month time span most of what I'm talking about.

Now Rob more Bakker who learns who leads our Germantown Maryland team is producing our production convertible city car mold.

So how do we do it?

We're modular.

The engine is able to be switched from a gasoline to electric engine in about the time it takes to change a tire.

The car body switches from a convertible to a pickup truck.

This lets us make changes and develop quickly.

Here you can see our chassis.

Our frame holds all the modules together .That chassis is the lightest chassis in the world to achieve a five-star crash rating equivalency.

Thanks so much.

We're safe because we design safety tests for our parts before we even build them.

In fact we design tests for all of our parts before we build them.

We take this from test-driven development in the software world.

You guys are awesome.

We use less stuff where ever we can hear Rob Huggins a Seattle area recent high school graduate is saving up for college and he's able to build a wikispeed car by using an $89 bandsaw and a home-built CNC router instead of a piece of equipment that costs more than a hundred million dollars in existing automotive process.

We reduced the cost to make change wherever possible costs in tooling machinery and complexity.

This lets us not have to wait three to seven years for the next version of our product again we're able to make changes to any part of the car every seven days.

We use distributed collaborative teams.These again increase our velocity and we found that morale is a multiplier for velocity across the team and the way we organize our teams is the smallest fastest way to organize an agile team it's called scrum.

Scrum is a method to manage a team in a very rapid way and that's exactly how we manage our teams in team wikispeed.

We do all our work in pairs.

This avoids time spent training that's not productive.

It also eliminates the need for most types of documentation.

Here Martin Val and Curt Roy are building one of our engines.

They actually both perfectly know how to do it but they're able to share all that knowledge while working without then having to up train someone afterwards.

We visualize our workflow to identify any time spent not creatively solving problems.

The tools we use to do this are all free.

And none of these existed ten years ago, that means this approach would have been difficult and maybe even impossible even five years ago.

Every industry Stentz stands to benefit from this process and in fact a probable future is that for businesses to maintain relevancy or even be able to compete they'll have to adopt this process.

So what to do?

If you own a business identify a member of your board of directors to be a process coach for the business and then add process coaches to your teams.

If you're the member of a team ask your process coach where you can gain efficiencies in your team, and if you're a process coach or a scrum master, identify the value stream map of your company and sharpen your skills at every opportunity.

So what's wikispeed doing next?

We're more than 100 volunteers in 8 countries.

We sell cars now and now we're taking these processes to solve bigger problems like help eradicate polio like help develop low-cost medical centers for the developing communities.

Join team wikispeed and let's change the world.

You'll sharpen your agile skills and make a difference in the world around you, but even cooler than that I invite everyone here to spend 2 hours a day even just two hours a week rapidly solving problems for social good many of the members of team wikispeed spend between 2 & 8 hours a week helping us rapidly develop our cars and we've had phenomenal and regular successes with it.

You we build ultra efficient cars, one of you might help eradicate rotavirus or develop simple maintainable distributed banking applications for the developing world, and that might be even cooler than watching TV or coaching Little League.

If everyone in this room spent even just two hours a week rapidly solving problems for social good it would be so awesome it would be like a gorilla high-fiving a shark in front of an explosion.

Thank you very much.